Asset Reliability

Boost Your Bottom Line by Eliminating Costly Downtime

While perfection can't hinder production, unplanned downtime significantly impacts your bottom line. Often, a single part or sub-assembly repeatedly causes lengthy or unexpected shutdowns. Our approach to maximize runtime and minimize production loss involves a comprehensive strategy: we audit your systems, assess the root causes of downtime, provide tailored recommendations, and execute a plan to implement solutions.

Our successful projects have included:

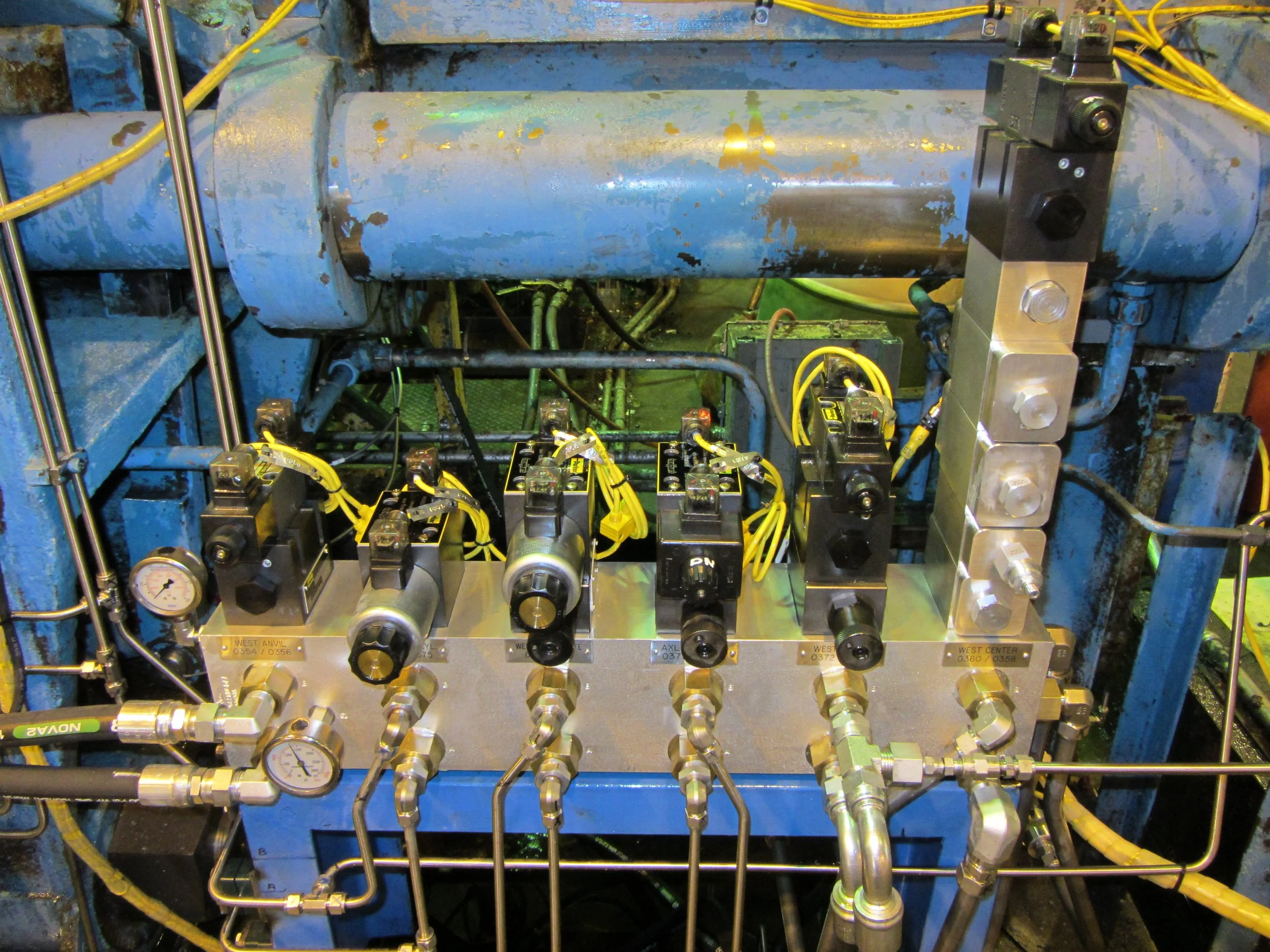

Updating aged or obsolete components, like hydraulic or control system parts.

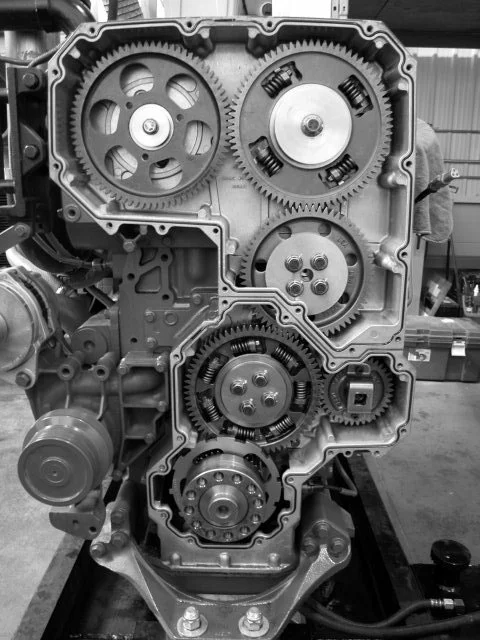

Redesigning critical elements such as shafts.

Specifying more durable components, including seals or pumps.

Optimizing system layouts by re-routing pipe circuits.

Improving alignment of machinery.

By addressing these common culprits, we help you achieve more reliable and efficient operations.