Engineering Design

Scroll down to see a few examples of completed projects.

Automated Grit Blast Machine

Tactic was commissioned to design and build a refit of a client's existing machine. While some components were reused, the majority were redesigned with the goals of improving process consistency through parameter monitoring, reducing labor, and increasing machine uptime. The project started with a Process Improvement Study to determine the optimal configuration for a new machine. Tactic managed the design through construction and worked with the client through testing and qualification.

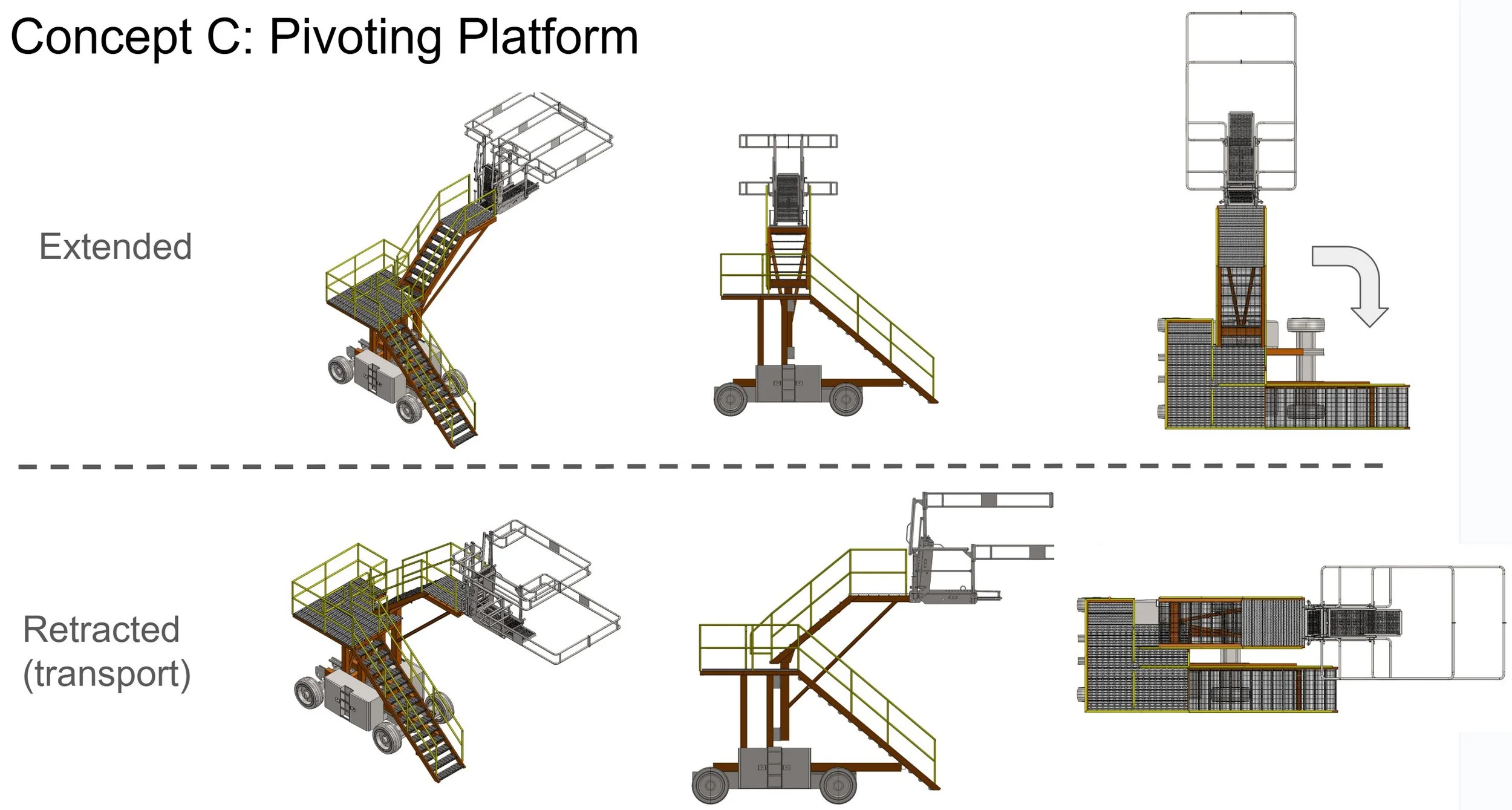

Mobile Access Platform

Tactic designed, tested, and commissioned a custom solution for railcar access. Several concepts were developed to fit on a surplus construction scissor lift and reach over existing pipe infrastructure. Tactic provided the fabrication drawings, overload and stability test plans, control system and hydraulic modifications, and on-site assembly, training, and certification.

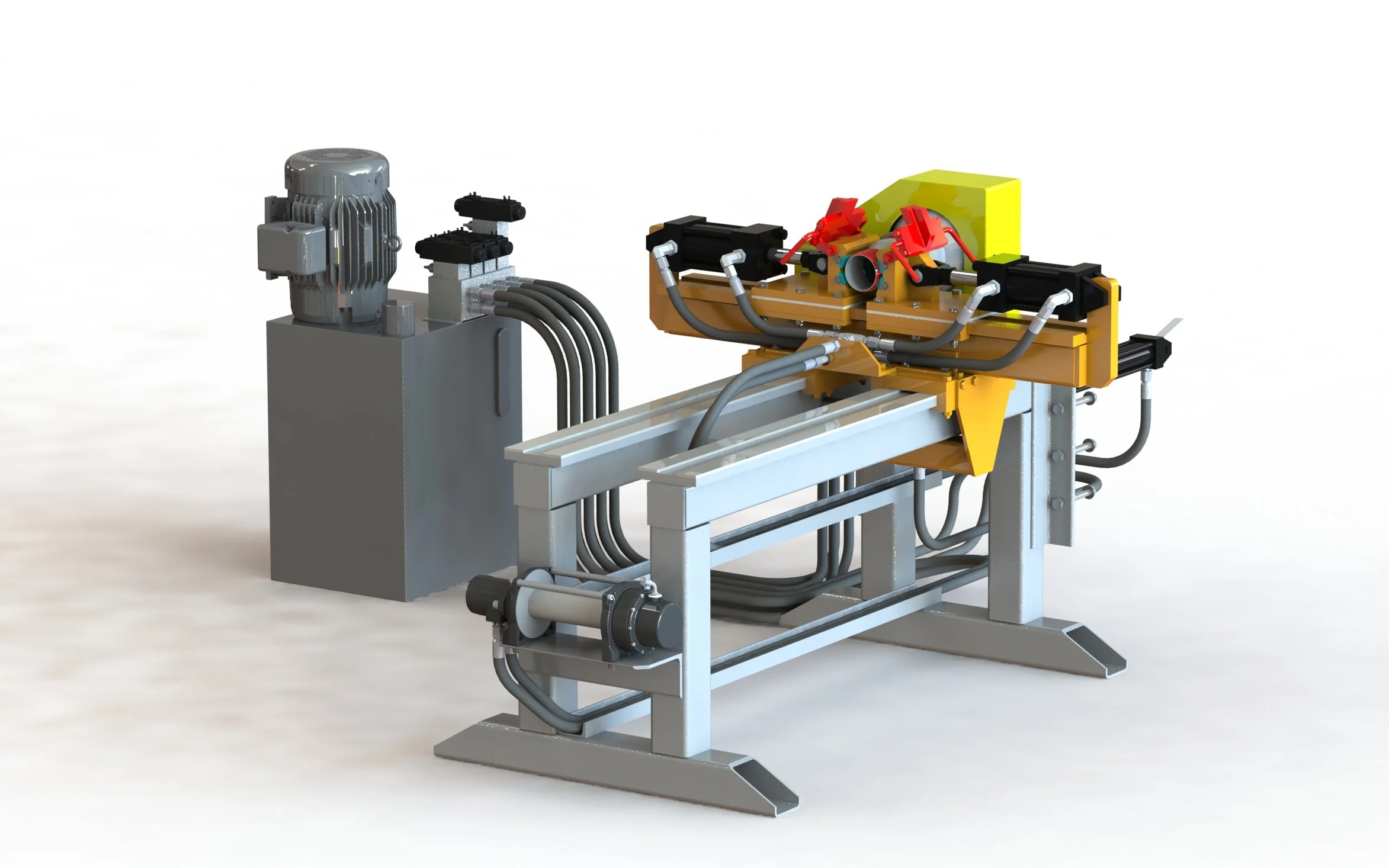

Downhole pump make/brake machine:

This equipment, designed for a progressive cavity pump test bench, was created to securely hold and efficiently install (thread and unthread) pumps. Its implementation significantly reduced cycle time and enhanced operator safety.

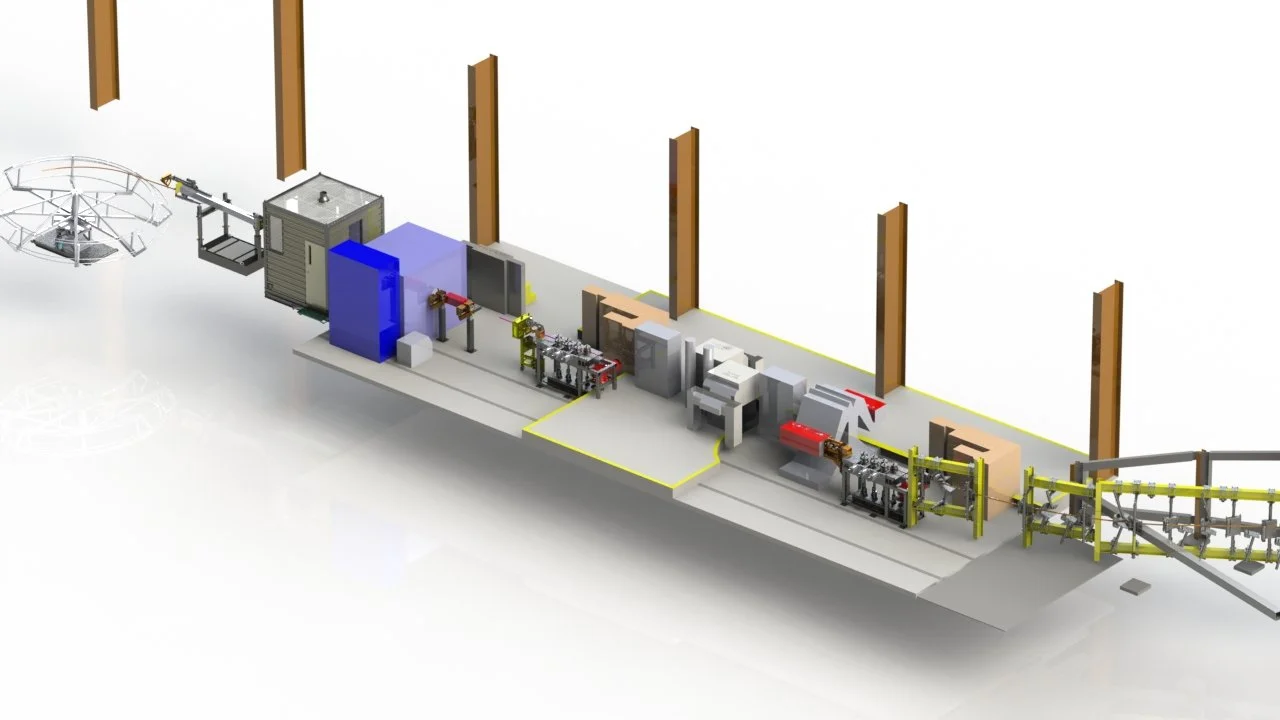

Automated powder coating integration and control system upgrade:

This project involved decommissioning a U.S.-based plant and integrating its equipment into an existing production line. As part of this process, the control system, with over 700 I/O points, was upgraded from obsolete hardware to newer surplus equipment provided by the U.S. plant. This required modifications to machines, updated plant layouts, and comprehensive testing and commissioning.

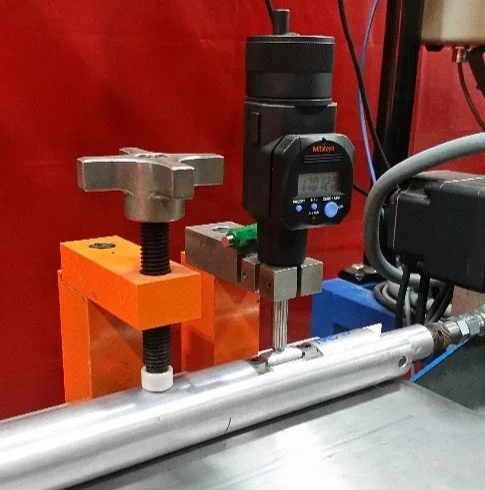

To upgrade an existing quality control system, a solution was required to replace the client's manual process of inserting a tool to measure the ID of progressing cavity pumps. An automated "lance" machine was designed for precise movement of the measurement tool along a 20-foot tube. Project scope included concept development, detailed design, on-site assembly, commissioning, and supervision of the gauge repeatability and reproducibility (GR&R) study.

Precision Measurement System:

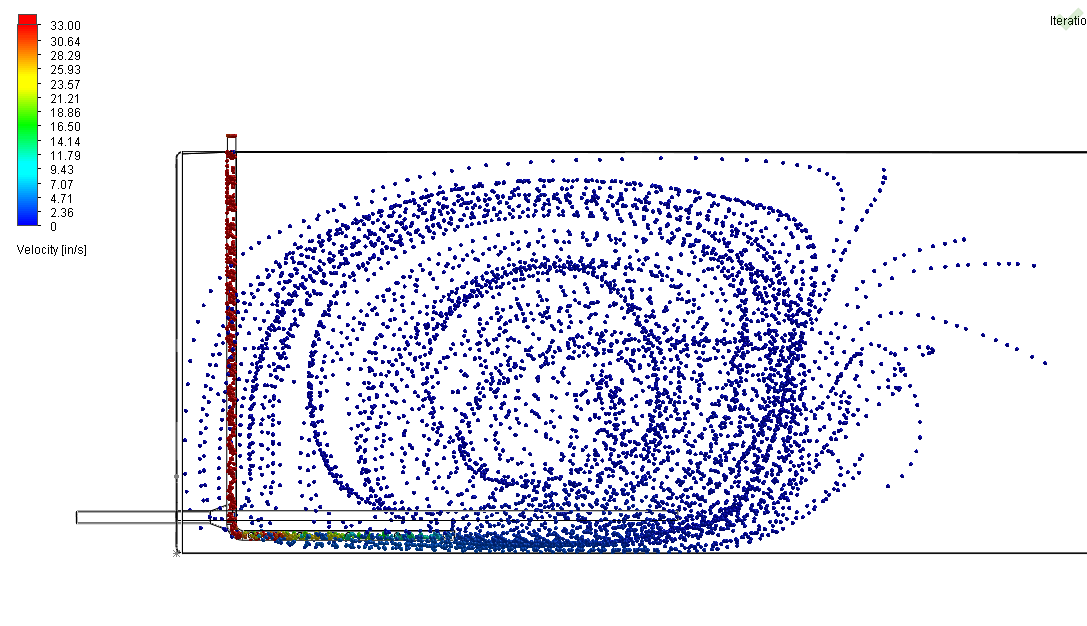

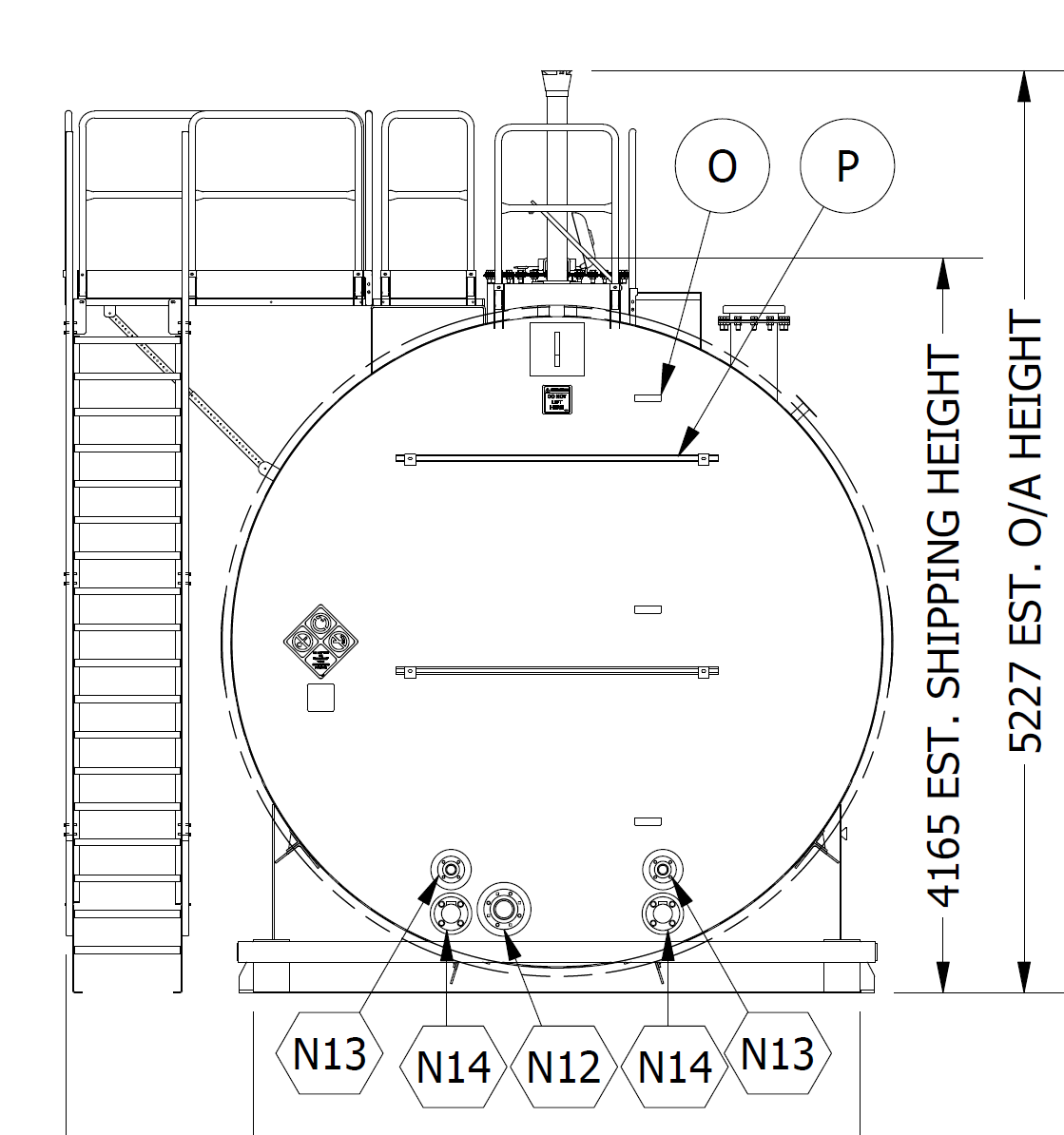

Biodiesel Holding Tank Design:

Tactic was hired to assist with the specification of a 150,000 L FAME storage tank. The project included calculating the heating and insulation requirements, developing a circulation scheme for the specialized product, reviewing vendor proposals and providing recommendations.

Cryogenic Process Vessel:

Designed for a proprietary process, this factory equipment immerses 20-foot steel tubes into 700 liters of liquid nitrogen.

50 Ton Freight Car Service Jack:

Designed for lifting rail cars and changing wheelsets.